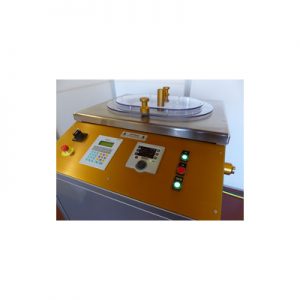

Chocolate processing: depositor D03

Simple filling machine with three nozzles. The moulds that are to be filled are automatically brought to the correct position with a conveyor belt, and the filling process is started automatically. As soon as the filling process has been completed, the mould is automatically pushed further until the mould has been completely filled. The filled mould is then transported out of the machine and the next mould is automatically detected and filled. The weight and/or volume of the filling mixture can be simply regulated with a hand wheel. The repeatability is very precise, and different cylinder diameters can also be used. The container and the nozzle can be heated.

Technical Data

| Description: | Machine for the filling of chocolate and chocolate filling mixtures. With frame and rollers. |

| Machine dimensions : | approx. 460 x 1’000 h : 1670 mm |

| Maximum mould size : | approx. 350 x 400 h : 50 mm |

| Capacity: | 5 to 15 strokes / min. Up to 45 fillings per minute Up to 675 g per minute |

| Description of the filling mechanism: | Precise filling with volume-controlled piston |

| Maximum number of pistons per row : | 3 piston |

| Accessories: | 3 fixed straight stainless-steel nozzles 3 piston, diameter 22 mm |

| Nozzle bar: | Nozzle bar slightly heated, but not regulated 03 piston positions spaced 35 mm apart |

| Containers: | Container slightly heated but / regulated Capacity: 5 litres |

| Filling volume per nozzle: | can be regulated approx 0.2 to 14 cm3 (0.5 to 15 g) |

| Placement of the moulds: | manual |

| Movement from row to row: | manual |

| Electrical power : | 230V./ 50Hz, 5A |

| Compressed air: | 6 bar / 50 litres per minute |

Options

| Additional equipment: | Container with 8 litre capacity, extra charge |

| Regulated temperature for container and nozzle barund Balken | |

| Second container |

Warning: Undefined variable $global_tab_title in /home/avgerisgroup/public_html/_w/wp-content/themes/porto/woocommerce/single-product/tabs/tabs.php on line 28