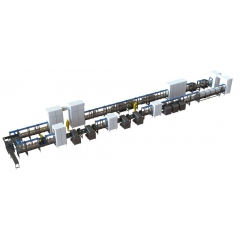

MODIMM MOULDING LINE

High output shell moulding line

Key features

Close loop moulding line with servo driven mould transports:

– Mould changer

– Mould pre-heating

– Choice of decorating options

– 3-stage moulding

– Three vertical cooling towers

– Automatic de-moulding, on belt, plates or directly in trays

– Typically used for bigger mould sizes

– Various options for granulate, nut, cherry or wafer depositing are available

– Optional book moulding or truffle ball mould handling

– Hacos tempering and piping are available

Our advise

From high output mono-product lines, up to flexible all-round moulding lines, Hacos will offer you a suitable solution.

Technical details

| Capacity | 500-2000 kg/h / 10-30 moulds per minute |

| Contence/Size | 275 up to 840 mm mould sizes |

| Floor space | 100-250 m² |

| Command pannel | Touch screen PLC |

| On wheels | No |

| Electrical connection | 3-phase + N + E |

| Compressed air connection | Yes |

Warning: Undefined variable $global_tab_title in /home/avgerisgroup/public_html/_w/wp-content/themes/porto/woocommerce/single-product/tabs/tabs.php on line 28